OUR CAPABILITIES

OUR ADVANTAGES

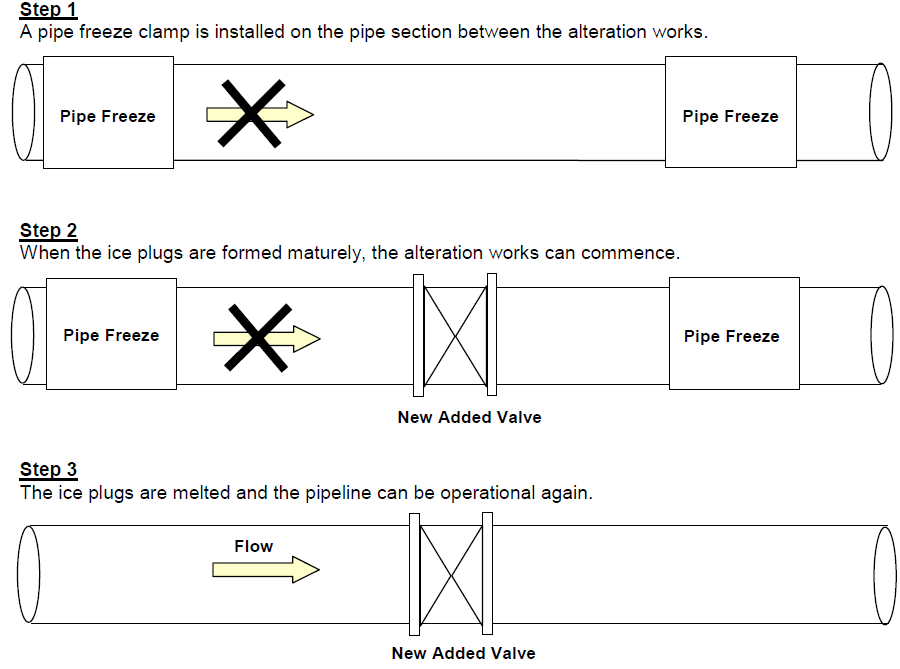

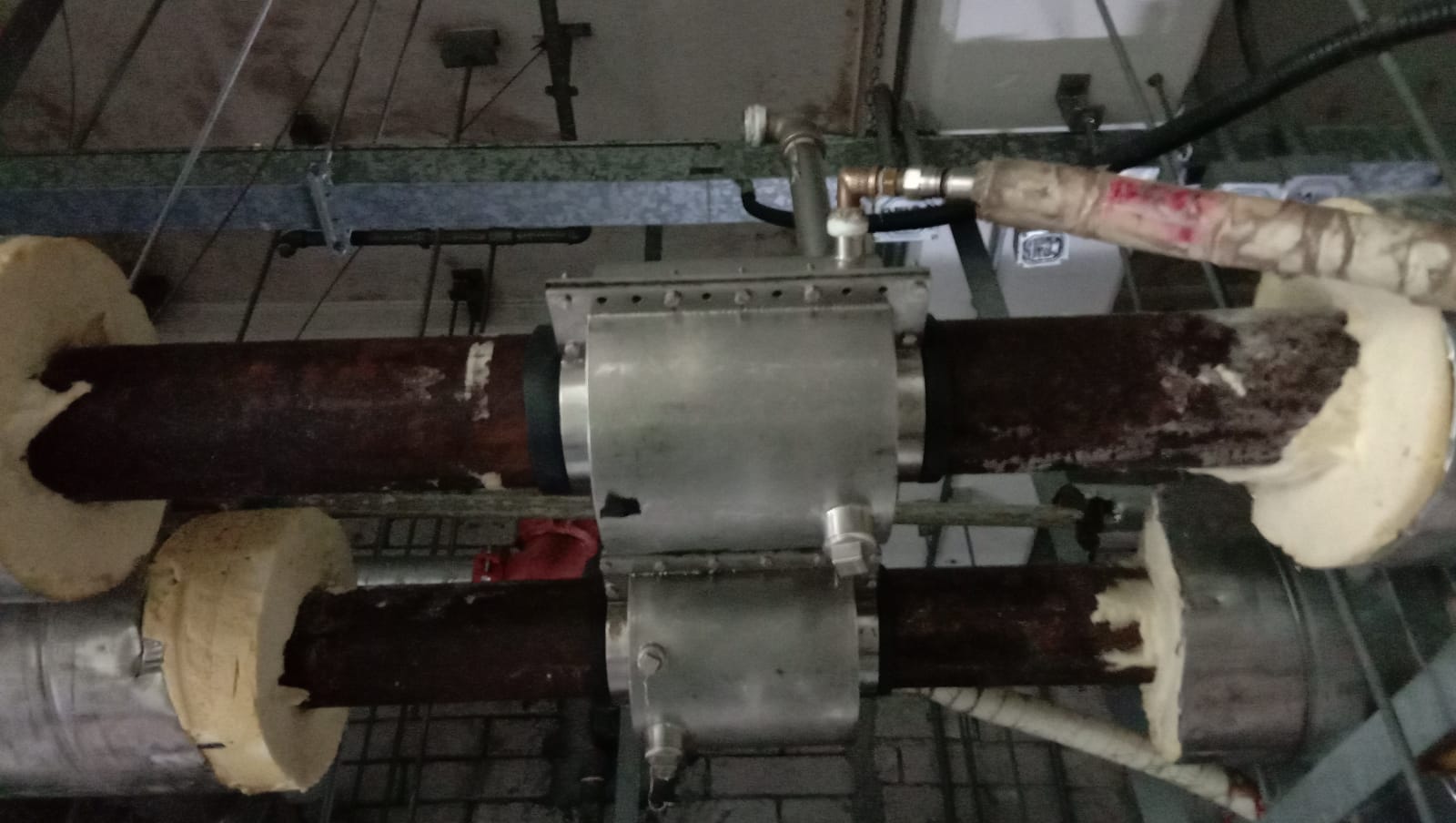

Freezing Jacket Installed

Freezing until formation of ice plug

Drain off water & observe the ice plug inside pipe

Perform hot work and pipe alternation

Numerous scientific studies have proven that frozen pipes break when ice is uncontrollably formed inside the pipe near to a dead-end or closed valve. As the ice forms, it seals off the internal of pipe, and then expands longitudinally, along the centre axis of the pipe, pushing on the trapped water. This push causes the pressure to rise in the entrapped unfrozen water area until it reaches a level that the pipe can no longer hold. The pipe then sometimes breaks. Highly involved testing has shown that radial expansion of the ice plug does not come close to exerting enough stress on normal piping systems to cause failure.

At Alstern Technologies, our pipe freezing specialist perform freezing in a controlled manner by monitoring the pressure and temperature of the ice plug “live”. Also, if necessary, we will install pressure relief equipment to monitor and control the internal pressure of the fluid. Therefore we achieve 100% success rates.

No. In fact there are types of steel that are "heat treated" to improve their performance properties by cryogenically quenching them. Extensive strain gauge, metallurgical and mechanical studies by independent laboratories have shown that no permanent damage or deformation occurs with Alstern Technologies pipe freezing.

First, ice has an amazingly high adhesion to steel. This, combined with friction of the long ice plug inside the irregular surface of the pipe would be enough to assure the ice plug isn't going anywhere. Additionally, the ice plugs lock themselves in place due to a phenomenon known as "hour-glassing". As the ice plug begins forming, the pipe cylinder being chilled temporarily elastically reduces in diameter at a localized area inside our equipment. The ice plugs then conform to this shape, having large ends on either side of a narrower middle. This dimensional change of the pipe is small and only lasts as long as we maintain the ice plugs. It is one of the reasons why our ice plugs can be used to hold back thousands of pounds of line pressure.

The question to you is how much pressure can your pipe hold? A "high pressure" ice plug can hold even when pressure behind it is raised to cause stresses greater than 100% SMYS of the pipe. In fact, full-scale tests even discovered that our ice plugs locked into a severely damaged pipe held these over-stresses. We have successfully freeze pipes with pressure of more than 25 bar.

Alstern Technologies is a safety-driven company. We know that pipe freezing is a well-engineered procedure with safety factors built into it. However, we do not want to impose any risk to our customers or working personnel. Therefore before we accept a job offer, we will perform a pipe inspection to ensure that the pipe is safe for freezing. If defects are present in a pipe, it will weaken the pipe structure and cause failure and lead to undesirable consequences.

There are some mechanical hazards while performing pipe freezing and alteration works. These may be impact or heat stress to the pipe near the freezing location. However, our pipe freezing specialist is able to supervise and provide professional guidance to ensure that the project is carried out in a safe manner.

At Alstern Technologies, our company philosophy is safety first - perfect execution of a job equals perfect and safe results. We know the hazards of handling cryogenic agents and we therefore take prudent precautions to assure a safe jobsite. That's why we insist on a large safety perimeter on a jobsite. Above all, we are concerned about the safety of working personnel on site.

Unit 2, 26/F, Global Gateway Tower,

63 Wing Hong Street, Cheung Sha Wan, Kowloon, Hong Kong

| Tel : | +852 2647 8163 |

| Fax : | +852 2647 4163 |

| Email : | enquiry@alstern-technologies.com.hk |