Pipe Spool Installation

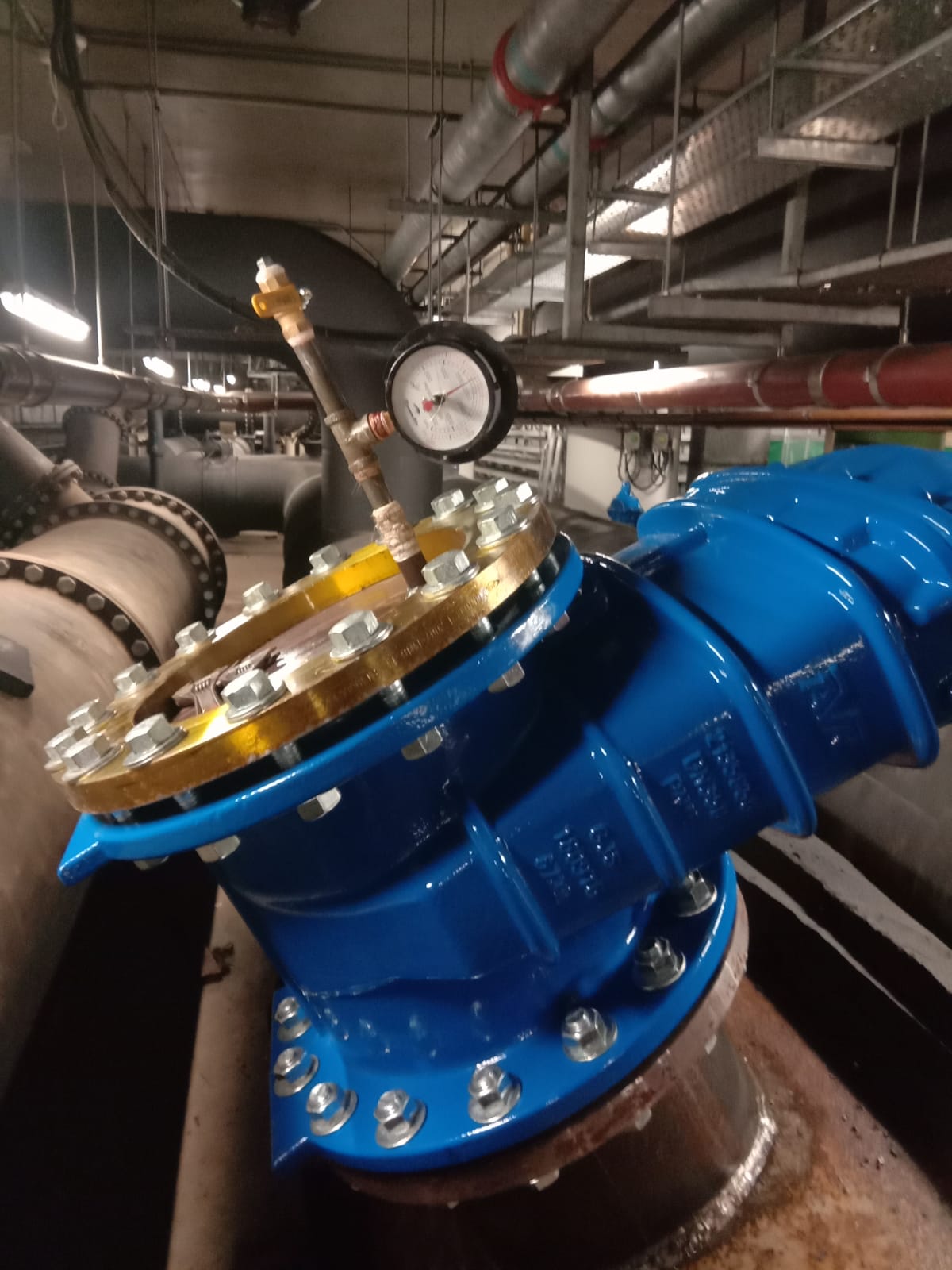

Pressure Test after welding work

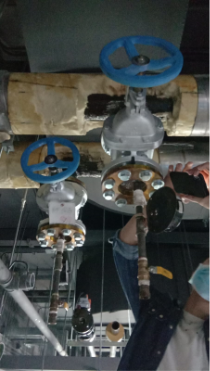

Hop Tap Operation

Collect the Hot Tap Coupon

Valve Close after hot tap

Blind of the gate valve

The components required for a typical hot tapping operation include a hot tap fitting designed to contain system pressure, a valve used to control the new connection and a hot tapping machine. The basic operation procedure is as follows:

Unit 2, 26/F, Global Gateway Tower,

63 Wing Hong Street, Cheung Sha Wan, Kowloon, Hong Kong

| Tel : | +852 2647 8163 |

| Fax : | +852 2647 4163 |

| Email : | enquiry@alstern-technologies.com.hk |